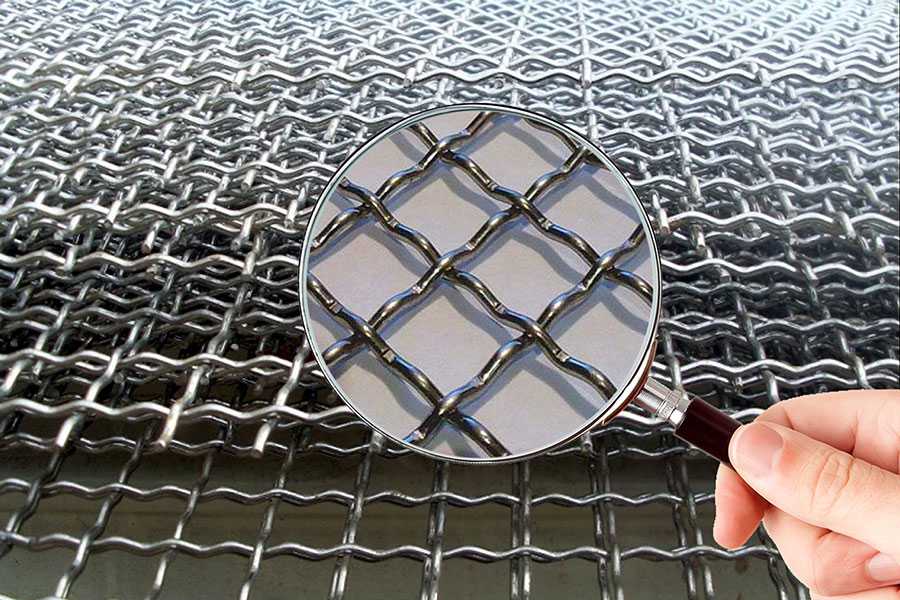

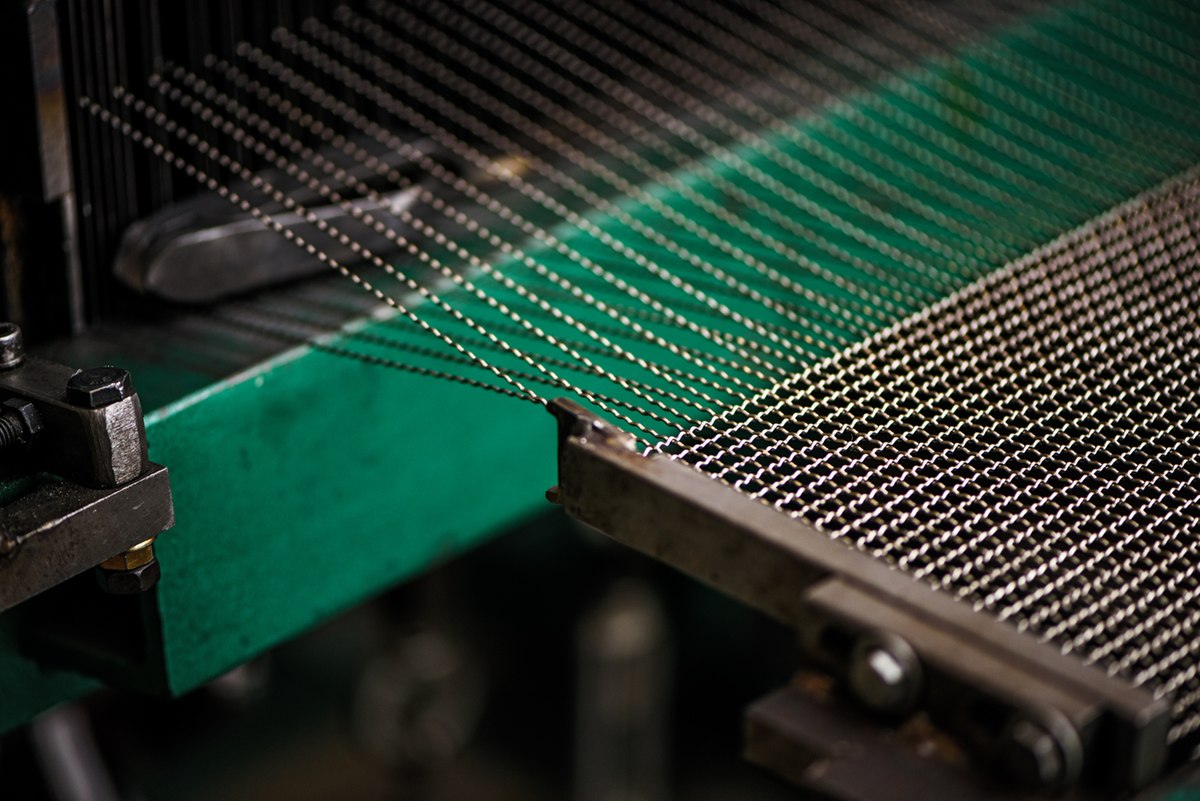

Pre-crimped Weave Styles of Wire Cloth Weaving. In the pre-crimping process, wire is first formed (crimped) in precision machines using rotary dies that precisely define the spacing of the wires and insure that the wires will lock firmly together at the intersections. The pre-crimped wires are then assembled in custom designed screen assembly machines (looms).

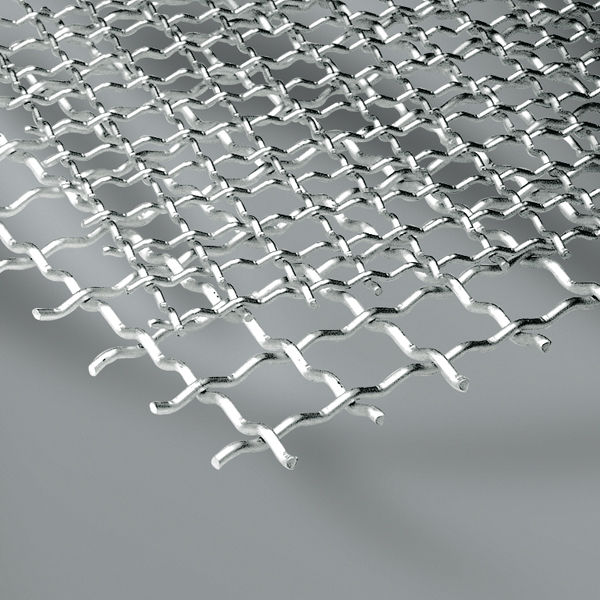

When open area is important, Extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.

Pre-crimped wire cloth has very accurate openings and is woven much tighter than plain weave. It is typically preferred for vibrating screens and many other applications where sizing is critical.

Specifiations

- Accurate and Consistent square and Rectangular Opening

- Opening Size Range from 3/8" to 4"

- Wire rods upto 20mm

- Can be manufactured in Stainless Steel, Spring Steel, High Carbon High Tensile, G.I. & M.S. Wire etc.